LIMITED TIME OFFER

Replace all of these

with a single tool for just $1 per month for your entire team

UNLIMITED USERS

UNLIMITED PROJECTS

UNLIMITED CHATS

UNLIMITED DOCS

UNLIMITED STORAGE

AND MORE..

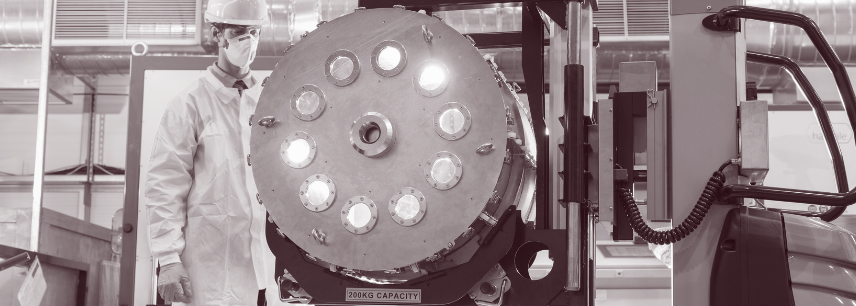

7 Ways Project Management Software Transforms Manufacturing Operations

In the manufacturing industry, efficient project management is crucial for the successful execution of complex projects, timely delivery, and effective resource utilization. Project management software tailored for the manufacturing sector can provide immense value.

In this listicle, we explore the scope of project management software in manufacturing and highlight best practices for leveraging it effectively.

1. Streamlining Production Planning and Scheduling

Project management software enables manufacturers to streamline production planning and scheduling processes. It allows for efficient resource allocation, capacity planning, and real-time monitoring of production progress. This helps optimize production timelines, reduce bottlenecks, and improve overall operational efficiency.

2. Manufacturing Project Management for Supply Chain and Inventory

Effective supply chain and inventory management are vital in manufacturing. Project management software can help manufacturers track and manage suppliers, monitor inventory levels, and streamline procurement processes. This ensures timely availability of materials and minimizes production delays.

3. Tracking Quality Assurance and Compliance

Maintaining quality standards and compliance is essential in manufacturing. Manufacturing management software facilitates tracking and monitoring quality assurance processes, ensuring adherence to industry regulations and standards.

It enables manufacturers to maintain detailed records, conduct audits, and address quality issues promptly.

4. Enhancing Collaboration and Communication

Manufacturing projects involve cross-functional teams and stakeholders. Project management software provides a centralized platform for collaboration, document sharing, and communication.

It improves coordination, facilitates real-time updates, and fosters effective communication among team members.

5. Monitoring Project Costs and Budgets

Controlling project costs is critical in manufacturing. Manufacturing project management software enables manufacturers to track project expenses, monitor budgets, and analyze cost performance.

It helps identify cost overruns, optimize spending, and improve financial control throughout the project lifecycle.

6. Integrating with third-party Software and Tools

To maximize efficiency, the software should integrate with existing manufacturing systems and tools.

The integration enables seamless data exchange, eliminates manual data entry, and enhances overall process automation. It streamlines workflows, improves data accuracy, and simplifies reporting.

7. Adhering Manufacturing Management Best Practices

To make the most of project management software in manufacturing, consider implementing the following best practices:

- Define clear project objectives, milestones, and deliverables.

- Establish a robust project governance structure and assign roles and responsibilities.

- Utilize standardized project templates and workflows.

- Conduct regular project status meetings and ensure effective communication.

- Monitor project progress using key performance indicators and metrics.

- Foster a culture of continuous improvement through lessons learned and feedback.

Project management software tailored for manufacturing offers valuable capabilities to streamline processes, enhance collaboration, and optimize project delivery.

By leveraging the scope of project management software and following best practices, manufacturers can effectively manage projects, improve resource utilization, and achieve successful outcomes.

Embrace the power of project management software in manufacturing to drive efficiency, productivity, and success.